Content

The construction of a greenhouse with polycarbonate sheathing is not a matter of several hours, but it is quite doable. The construction is serious, so you will have to spend a little time on the drawings. The dimensions of all elements indicated in the diagram will help speed up the process of manufacturing the structure. So, now we will consider how to independently build a polycarbonate greenhouse, and what nuances must be taken into account in this case.

Determine the dimensions of the frame

Before starting to develop drawings for a greenhouse or greenhouse, it is necessary to determine the dimensions of the structure. In turn, several important nuances affect the calculations:

- It is immediately important to determine the place where the installation of the polycarbonate structure will be carried out. First, it is important to measure the size of the free space on the site. It depends on whether the greenhouse or greenhouse of the desired size will fit.

- The contours of the future foundation are drawn on the site. Its shape and size will accurately outline the parameters of the building being erected.

- The amount and size of building material plays an important role in determining the size of a greenhouse or greenhouse. With the availability of material, everything is clear, because it is impossible to build, for example, a 3 by 6 greenhouse if the profile or polycarbonate is only enough for a 3x4 greenhouse. With regard to the size of the material, consider an example on polycarbonate. Sheets are produced in standard dimensions 2.05x3.05 m. It is advisable to use them sparingly so that there is less waste. Greenhouse frames 3x6, 3x4 or 3x8 are ideal for polycarbonate.

Having dealt with all the nuances, we directly proceed to determine the size of the greenhouse or greenhouse.

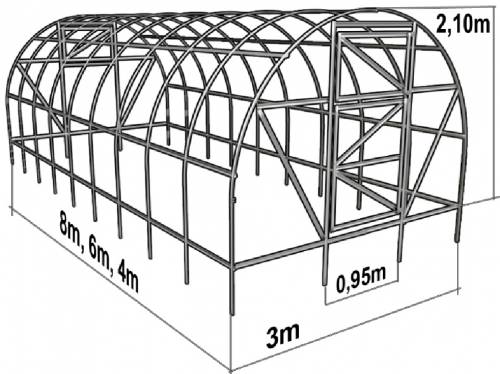

Most gardeners have a general opinion that it is better to install collapsible greenhouses of small sizes from ordinary film. It is optimal to use polycarbonate in stationary large greenhouses, of course, within reasonable limits. A good owner is unlikely to have an empty space in such a greenhouse. The most popular size of a polycarbonate structure is considered to be 3 by 6. If desired, the length is increased to 8 m or reduced to 4 m. As a result, the optimal dimensions of the greenhouse are 3x4, 3x6 and 3x8 m. And as already noted, for any length of the frame, the optimal width remains in within three meters.

When calculating the dimensions of a greenhouse or greenhouse, they are guided by the following considerations:

- The width of the structure is the most important indicator... The convenience of caring for plants will depend on this. The more space, the less likely it is to damage the garden bed or snag on the shelves while working. Determine the width of a greenhouse or a stationary polycarbonate greenhouse based on the fact that: the minimum door width is 60 cm, the optimal width of shelves or beds is 1 m and the width of the passage is 60 cm.It turns out that it is advisable to stop for comfortable maintenance of a stationary polycarbonate greenhouse at a minimum width of 2.4 m.

If we take into account that a person of an obese physique or, they will enter the greenhouse in a wheelchair, then the passage must be expanded to 1.2 m. That is why the standard width of 3 m of a greenhouse or polycarbonate greenhouse is adopted. - The length of the polycarbonate greenhouse has no restrictions... It all depends on the number of pallets installed inside for growing seedlings or the size of the beds. Let's say we have standard pallets with a size of 28x53 cm.It is necessary to decide how they will be installed inside the greenhouse: along or across. From here, a value is taken as a multiple of 28 or 53, multiplied by the number of pallets in one row, and the maximum length of the greenhouse is determined. However, it is important to remember the standard sizes of polycarbonate sheets. The maximum profitable use of material with minimal waste will be obtained in greenhouses with a length of 4.6 and 8 m. Too long greenhouses and greenhouses are unprofitable in terms of maintaining an optimal microclimate. With the onset of cold weather, the cost of heating the interior space will increase.

- The height of the building depends on the selected type of shelter. If this is a small greenhouse for one narrow bed, then the height can be made about 1 m. Then you will have to provide an opening top to access the plants. In large greenhouses measuring 3x4, 3x6 and 3x8 m, it will be inconvenient to walk with a low ceiling. According to existing standards, the height of a stationary structure reaches 1.8 m. If you make a polycarbonate structure with your own hands, then it is better to stop at a height of 2 m. This can result in a takeoff run of 10–20 cm, depending on the shape of the selected roof.

Having decided on the dimensions of the future polycarbonate structure, they begin to draw up drawings.

The video shows a mini-course on maintaining the size of the greenhouse:

We draw up an exact drawing

They begin to draw up drawings with rough sketches of how the future greenhouse will look like. The roof can be made semicircular, gable or single-pitched. If a large greenhouse is taken, then an arched roof is considered the best option. It is easier to cover it, since polycarbonate bends well, and little precipitation is retained on a semicircular surface.

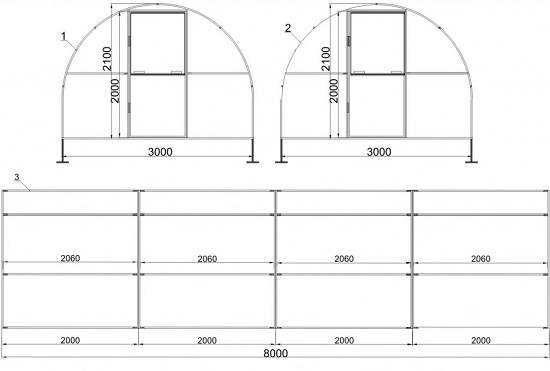

In the arched construction made of polycarbonate, the ends are the same. It is not necessary to make drawings of both sides. It is enough to sketch a sketch of one end, indicating the dimensions. The same is done with the side view diagram, because these sides are similarly the same.

A diagram of the ends and a top view of a polycarbonate greenhouse, the photo of which is presented below, indicate the dimensions of an arched structure measuring 3x8 m.

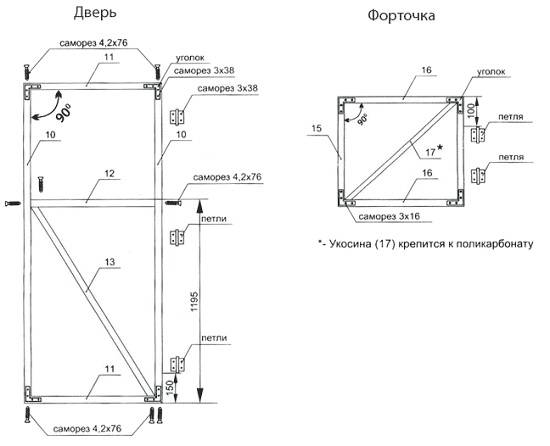

The following photo shows how to make a drawing of doors and windows of a polycarbonate greenhouse. It is important to indicate on the diagram all fasteners, welding points and the use of hardware.

If desired, a plastic door can be bought ready-made. It is already equipped with hinges and a handle, which will simplify the process of making a greenhouse or greenhouse with your own hands made of polycarbonate.

We equip the foundation for a greenhouse or greenhouse

Polycarbonate is a lightweight material, and so that a large greenhouse or greenhouse is not moved by the wind, the structure is fixed to the base. Guided by the dimensions and shape of the future polycarbonate structure, it is necessary to make drawings of the foundation.

When everything is ready, you can start marking the site. First, the area is cleared of debris and vegetation. Further, the made drawings of the foundation are transferred to the ground. The markings are best done with stakes, between which the cords are pulled.

The following types of foundations are installed under a greenhouse or a stationary polycarbonate greenhouse:

- If it is supposed to install a small stationary polycarbonate greenhouse, then a point foundation is enough for such a structure. It represents the reference points only in those places where the greenhouse frame posts will be installed. Supports can be made from logs, asbestos pipes, concrete blocks. To do this, it is enough to dig the supports into the ground to a depth below the level of soil freezing.

- For a collapsible greenhouse or polycarbonate greenhouse with your own hands, you can make a foundation from a bar. First, a trench 200 mm wide is dug around the perimeter of the frame. The bottom and sides are covered with roofing material to prevent wood from rotting.The timber is treated with a protective impregnation, and then laid in a trench. At the end of the season, if necessary, the greenhouse and the foundation are quickly disassembled for winter storage under cover.

- A block foundation is built under a stationary greenhouse or a large greenhouse. First, a trench 250 mm wide is dug along the dimensions of the frame. The depth is determined by the level of soil freezing. This indicator is different for different regions, but not less than 800 mm. The bottom of the trench is covered with gravel 100 mm thick. Hollow blocks are laid out on top of the pillow, interconnected with cement mortar. The installation of the greenhouse frame on the foundation is carried out two days after the solution has solidified.

- The tape type of foundation is similarly suitable for stationary greenhouses or polycarbonate greenhouses with your own hands, and it does not matter what material the frame is made of. For the construction of the foundation, a trench is dug the same as for the block base. The bottom is covered with gravel with sand 150 mm thick. The sides of the trench are covered with roofing material, and formwork is knocked down from the boards on the surface of the earth. The height of the sides must be at least 200 mm. A reinforcing frame is laid inside the trench from rods, after which everything is poured with concrete. The installation of the frame of the greenhouse or greenhouse begins no earlier than 20 days later. The concrete must be completely cured.

When the foundation is ready, you can start making the frame of the greenhouse.

Assembly and installation of a greenhouse or greenhouse frame

Now we will look at how to install an arched frame of a greenhouse or greenhouse, designed for sheathing with polycarbonate. It should be noted that wooden blocks cannot be bent in a semicircle. When making an arched frame yourself, it is better to use a metal pipe or profile.

Suppose there are ready-made arcs available, and you can start assembling the greenhouse frame:

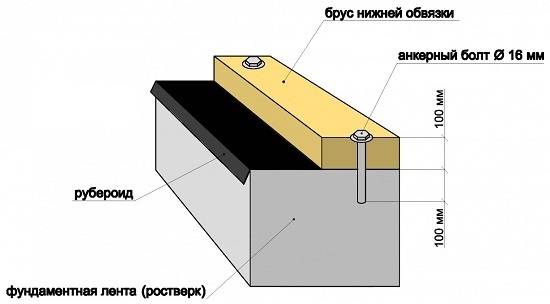

- Alternatively, a polycarbonate greenhouse can be installed on a timber previously fixed to the foundation with anchor bolts. But before doing this, the base is covered with a strip of roofing material for waterproofing the wood. A frame is assembled from a bar with a section of 120x50 mm along the perimeter of the foundation. It is important here to level the structure. Anchor bolts have a pitch of 500-600 mm.

- Installation of the frame on the timber is performed using a metal corner. It is placed one on each opposite side, where the profile post will be installed. At the same time, the installation points are marked on the bar, and measured so that they are at the same level. This time, they measure not the horizontal, but the verticality of the corners.

- The assembly of the greenhouse frame itself begins from the end walls. On the front wall, the roof arch with the spacer is bolted to the door frame with bolts, and then the end posts are attached. The rear end wall is assembled in the same way, but without a door.

- The finished end walls are placed on the foundation, bolted to the metal corner. To prevent the sections from falling, they are temporarily propped up with props. The end walls are fastened together with intermediate spacers. When everything is ready, all other intermediate arcs are installed. Each arch with uprights is attached to a metal corner on a bar.

- All nodes of the greenhouse frame are connected using special clamps - crabs. They firmly wrap 3 or 4 profiles, forming a T-shaped connection and a cross. At the same time, the two crab elements are firmly tightened with bolts.

- When all the arcs are installed, they are reinforced with longitudinal struts. The final assembly of the greenhouse frame is the constriction of all bolted connections.

The greenhouse frame is ready, you can start sheathing with polycarbonate.

The video provides instructions for installing the greenhouse:

Fastening polycarbonate

I start covering the greenhouse frame from the ends. Polycarbonate is leaned against the wall and, without cutting, is fixed to the frame. A firmly fixed sheet is now more convenient to cut with a jigsaw. First, a semicircle is cut out along the contour of the arch. Further, fragments of vents and doors are cut out in polycarbonate.

When both ends are sewn up, the top and sides of the frame are covered with polycarbonate sheets. The sheets are placed across, carefully bending on a semicircular arch. The joints are connected with a special docking profile. Polycarbonate is screwed to the frame elements with hardware with sealing washers. In this case, the holes are pre-drilled.

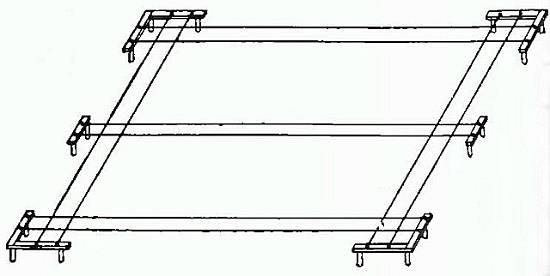

There is another way of attaching polycarbonate to the greenhouse frame using tie-down straps. In this case, you do not need to drill holes. On top of the polycarbonate, metal strips are straightened throughout the entire body of the greenhouse or greenhouse, after which they are tightened with tension screws.

When the frame of the greenhouse is completely sheathed, the protective film is removed from the polycarbonate. This must be done immediately, otherwise it will stick to the sun.

The video shows the process of attaching polycarbonate:

On this, the polycarbonate greenhouse is ready, it remains to install the doors, a window and proceed to the internal arrangement of the beds.