Content

Snow drifts significantly complicate the movement of people and cars in winter, so every inhabitant of the country tries to fight the snow to one degree or another. It is customary to clean paths, parking spaces and areas with a snow shovel. This type of hand tools has many varieties, but the most convenient option is the drag scraper. This shovel has a large bucket and is capable of picking up a lot of snow, which increases productivity. Scraper-drag for snow removal can be made of various materials with the introduction of some design features. In our article we will try to talk about the most famous types of scraper, determine their advantages and disadvantages, and also give detailed information on how to make a scraper with your own hands.

What is the difference between a scraper and a conventional shovel

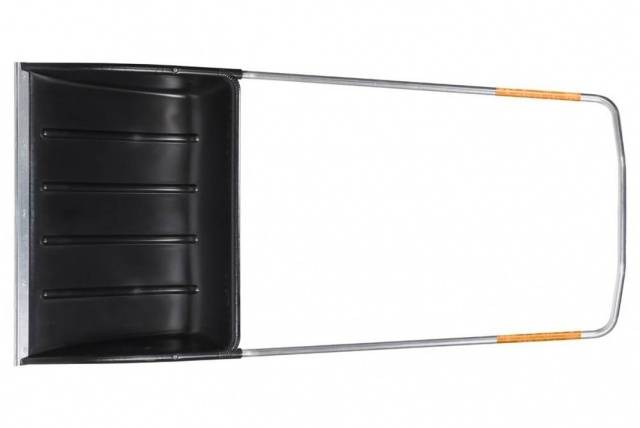

The drag scraper is a modernized analogue snow shovel... It is a simple design in which a large bucket is securely fixed to the handle. The bucket width varies from 70 to 120 cm. These parameters allow you to shovel a large amount of snow in one "pass".

In scrapers, the design of the handle is of particular importance. It can be T-shaped or U-shaped. The choice of this or that option largely depends on the dimensions of the bucket: it is convenient to move a large mass of snow with two hands, therefore wide buckets are often equipped with a U-shaped handle, which allows you to do this.

It should be noted that all drags are intended only for shoveling snow into a pile. It is not possible to lift and throw snow with a scraper. This is the main difference between the scraper-drag and a conventional snow shovel.

Variety of scrapers

Numerous manufacturers of garden tools are trying to create the most convenient, reliable and at the same time inexpensive snow shovels. However, the quality, cost and ease of use largely depends on the material from which the tool is made. It is also important to pay attention to its design when choosing a snow shovel. Some, at first glance, insignificant nuances in the design of a particular model can become reliable helpers in your work.

Material for making

For the manufacture of drag scrapers, manufacturers use metal, plastic and wood. Durability, weight of the shovel, ease of use largely depends on the material:

Plastic drag scrapers

Plastic drag buckets can be made from cheap polypropylene or more expensive polycarbonate. The cost of the material affects the cost of the scraper itself. But it is worth remembering that when buying a shovel, the higher cost will most likely be justified: polypropylene equipment is able to withstand strong shocks and frosts down to -400With no damage, while cheap polypropylene will surely fail on the first collision with caked snow.

All types of plastic shovels have two main advantages:

- Plastic is not subject to corrosion and decay.

- The light weight of the shovel makes it easier to clean the area.

Manufacturers of plastic scrapers try to protect their tools from breakage as much as possible, so many models have a metal plate along the bucket edge, designed to cut the thickness of snow. The presence of the U-shaped handle is also a kind of reinforcement in the overall design of the shovel.

Wooden drag scrapers

Only a few manufacturers produce wooden scraps for snow removal. The thing is that, along with a low cost, a wooden shovel has a lot of disadvantages:

- The wood scraper has a substantial mass.

- Wet snow often sticks to wood surfaces.

- Upon contact with moisture, wood absorbs water, as a result of which it deforms, swells, and increases its weight.

- The tree is prone to rotting.

- With regular use, the wooden scraper gets chipped and damaged.

Thus, wooden drag scrapers have an affordable cost, but their use is not the best option for snow removal.

Snow scrapers

Many manufacturers make drag scrapers from steel alloys or aluminum. These materials are highly reliable in operation. Their term of use is practically unlimited. The proposed types of metal are relatively light, snow does not adhere to them. The cost of metal snow shovels is available.

When purchasing a metal scraper, you need to pay attention to the back of the bucket. For greater reliability and durability, conscientious manufacturers provide for the presence of special stiffeners, which exclude deformation of a wide metal sheet.

Metal for the manufacture of the handle

When the scraper is working, a very large load falls not only on the grabbing bucket itself, but also on the handle. After all, the principle of operation of the scraper is based on the fact that the worker rests on the handle, thereby moving the shovel and shoveling the snow.

It is most convenient to work with a scraper-drag with a U-shaped handle. For its manufacture, plastic or metal can be used. The most reliable option is a lightweight aluminum handle.

Scraper buckets that are not too wide can be fitted with a regular straight handle or T-bar. In this case, the manufacturer can use not only plastic or metal, but also wood.

The scraper handle, made of metal, can be telescopic or foldable. The telescopic design allows you to "adjust" the size of the device to the height of a particular worker, and solves some special problems. For example, a retractable telescopic handle allows snow to be cleared off the roof.

The foldable handle makes the snow shovel extremely compact and easy to store. This advantage is also inherent in equipment with a telescopic handle.

Design or ergonomics

Some models of scrapers may seem strange to the buyer due to their unusual shape. But the original appearance can be justified not only by the design approach, but also by ergonomic requirements. A curved bucket or handle often helps a worker complete a task. The size, shape, plane of each element in this case has its own meaning:

- The flat scraper bucket is not capable of picking up large amounts of snow. To keep the thickness of the snow cover, manufacturers provide for the presence of limiters on the rear edge and side walls. The higher the walls and the deeper the bucket, the more snow it can move.

- The curved shape of the bucket allows you to overcome small obstacles as comfortably as possible, to move the snow caps without any effort.

- The scraper handle is often made curved so that the force applied to move the shovel is used as efficiently as possible.

Thus, even the most "wonderful" shovel can be extremely convenient to use. True, one can only be convinced of this through personal experience.

Scrapers on wheels

Some scraper models are equipped with casters. This element of mechanization allows you to reduce the load on a person during work. To overcome some obstacles, the scraper can be lifted slightly by resting on the wheel axle. Working with the scraper on wheels is easy and simple. A photo of such inventory can be seen below:

Hand-held bulldozers are a worthy alternative to scrapers. They are a metal blade rigidly fixed to a wheeled cart. This device allows you to shovel snow. Unfortunately, it will not be possible to lift a load with such a device.

Another variant of the scraper is widespread abroad, which provides for fixing the handle by means of a hinge on a wheel of large diameter. Such a scraper allows you to effectively rake and move the snow cover. The design is distinguished by its high cross-country ability.

Highly specialized scrapers

It is necessary to remove snow in winter not only from pedestrian paths and platforms, but also from roofs of houses and car windows. For such needs, special devices are provided, which are also called scrapers.

The snow scraper is a flat, narrow bucket mounted on a long telescopic handle. This design allows roofs to be cleaned at the attic level.

You can see another original design of a scraper for cleaning snow from the roof in operation on the video:

The scraper (scraper) for cleaning car windows is distinguished by its compact dimensions and soft material of manufacture, the presence of a comfortable ergonomic handle. The scraper blade must be made of reliable polymer materials that are able to remove snow efficiently without damaging the glass.

Introduction to some of the scraper models

Having understood a little with the design, material and purpose of scrapers, you can pay attention to some common models of this equipment, evaluate their cost, advantages and disadvantages.

SnowXpert 143021

Scraper model SnowXpert 143021 can be called one of the most reliable. It is produced by the well-known company Fiskars. The scraper bucket is made of high-strength, frost-resistant plastic. The bucket is 72 cm wide. The rim is protected by a metal plate. The shovel handle is made of lightweight and durable aluminum. If necessary, the handle can be adjusted in height. The SnowXpert drag scraper costs about 3.5 thousand rubles. Among the shortcomings of the model is the lack of the ability to arrange a shovel for compact storage.

Gardena 3260

Another high quality plastic scraper can be found under the brand name Gardena 3260. Its working width is 70 cm. The edge of the scraper is protected by a reliable, durable blade. The aluminum inventory handle can be lengthened or folded as needed. Perhaps the only drawback of this model is the overpriced, which is 5.5 thousand rubles.

SibrTech

A metal scraper of domestic production with a curved working surface is characterized by an affordable cost and reliability. The width of its bucket is 75 cm. The material of manufacture is steel alloy. The main disadvantage of the model is the absence of a rubber pad on the handle and the absence of sides. The cost of the scraper is approximately 900-1000 rubles.

Scraper for cleaning the roof Instrum-Agro

The scraper for cleaning snow from the roofs has a narrow bucket and a telescopic handle, the length of which can be increased up to 6.4 m. The scraper bucket itself is made of polypropylene. The cost of such inventory is 1.5 thousand rubles.

The cost of scrapers is quite high, and the device is distinguished by its simplicity. That is why many craftsmen prefer to make their own equipment for cleaning snow.

How to make a scraper with your own hands

If desired, a reliable and durable scraper can be made by hand. This will require absolutely accessible materials, some tool and a little time. We will offer only one simple option for making a do-it-yourself scraper:

To make a metal shovel with a wide bucket, you will need:

- A sheet of metal (preferably aluminum), 60 * 40 or 70 * 40 cm in size.

- Metal tape 3 mm thick.

- Shank.

- Rivets.

The principle of making a scraper is as follows:

- Cut 3 pieces from the metal tape. Fix one of them perpendicular to the main blade on the back edge of the bucket and two on its sides. It is necessary to fasten the metal with rivets.

- Make a hole for the handle on the back vertical edge.

- Make an oblique cut on the handle from one edge. Attach it to the base of the shovel and fix it with a countersunk self-tapping screw.

- Additionally, the handle should be fixed to the base of the bucket with a metal plate and rivets.

Another option for homemade scraper can be seen in the video:

A detailed manufacturing guide will help even a novice master to cope with the task at hand.

Conclusion

The drag scraper is a worthy replacement for an ordinary snow shovel. Its main difference is ease of use and high performance. With such simple equipment, even the largest areas can be cleaned very quickly and easily. Due to its high efficiency, this type of shovel is used not only in private buildings, but also in public utilities. Everyone will certainly be able to choose the right scraper model from a wide variety of models on the market. And if you wish, you can make your own reliable inventory for personal use. We offered all the necessary information in order to make a successful purchase or competently make a tool with our own hands.